Let me start by saying that I love Northern Brewer, shop there, and in no way mean this as an attack on them. The whole point of this post is to educate Texas homebrewers in specific and all homebrewers in general about the legal implications of purchasing certain pieces of laboratory equipment.

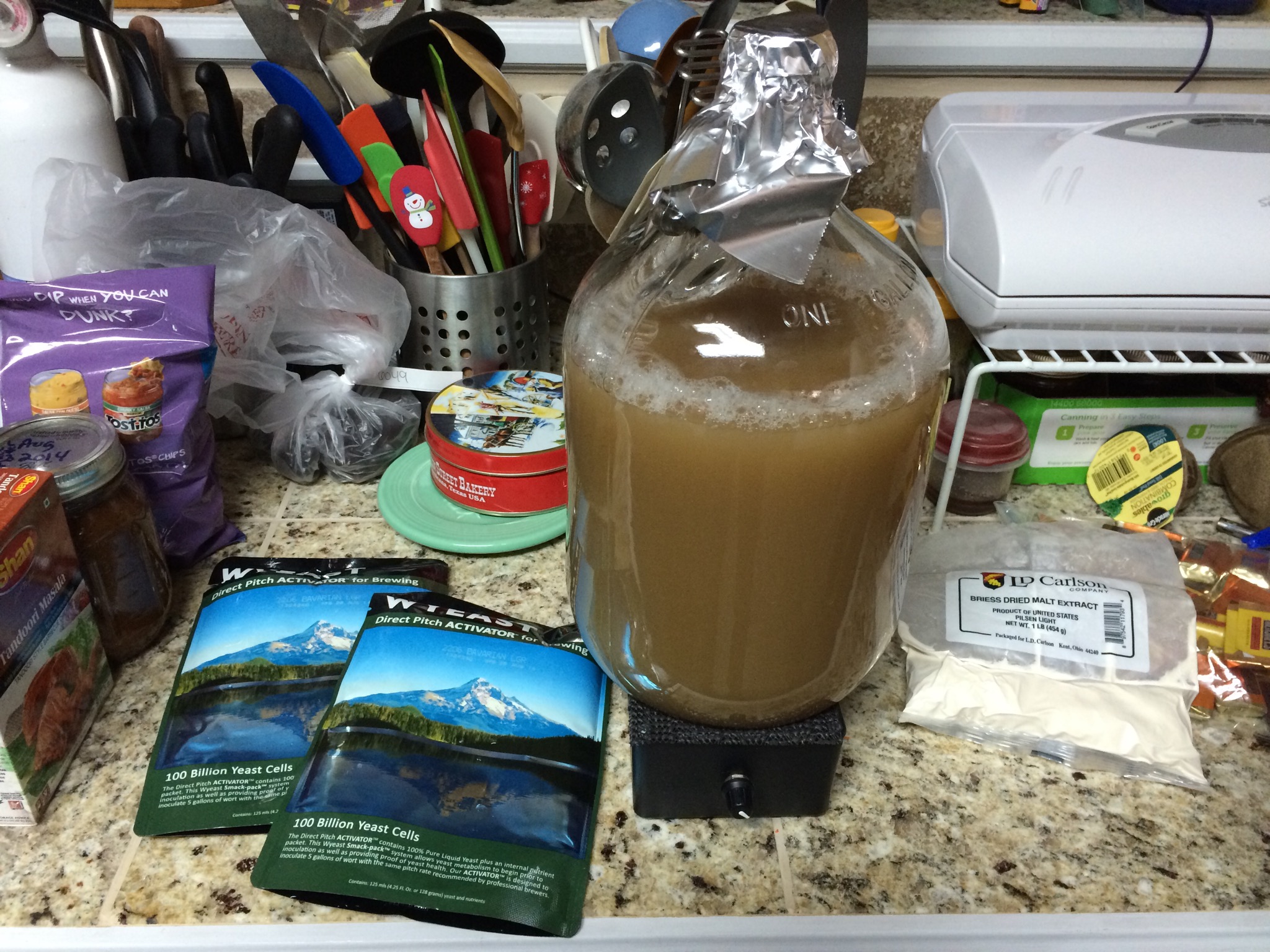

I got a promotional email from Northern Brewer this weekend, advertising a package deal where if you buy their Maelstrom digital, programmable stir plate, they’ll throw in a free 2000ml Erlenmeyer flask and stir bar. I’ve got an analog stir plate that I use to stir my starters, and it works really well, producing really good starters. If you don’t have one, you really should pick one up, because they make better starters.

That being said, it’s not the stir plate that’s the problem here, it’s the Erlenmeyer flask. The State of Texas considers Erlenmeyer flasks to be drug paraphernalia (Texas Health and Safety Code Title 6, Subtitle C, Chapter 481, Subchapter A, Section 481.002 (53)(H)) and also, in Section 481.138(b) sets the penalty for possessing that flask to be a state jail felony.

It’s not all doom and gloom though. The Texas DPS has a process by which you can get a permit to legally purchase and possess that flask. The permit is free, and is good for the life of the item specified. You do not need to renew it once you’ve got it. The application process is simple, but know that you’re probably going to get a visit from a State Police Officer. He or she will talk to you about what you’re going to be using it for, and yes, making yeast starters for homebrewing is a legitimate use. They’ll also want to see where you’re going to be storing it when it’s not in use because leaving them out is not acceptable. A gun safe is a good option, but make sure you’ve got somewhere to secure it. My interview was fast, the officer was polite and professional, and knew quite a bit about homebrewing.

After you’ve completed the interview process, they’re more than likely going to approve the permit, unless you don’t have a secure storage location. They’ll head back to the office, dot their Is, cross their Ts, and you’ll get the purchase permit in the mail. Hang on to that, you never know when you’ll need it later. Give one copy to the seller and keep a copy for yourself.

I live in Texas, so obviously this is very specific to Texas laws. Check your state’s laws before you accidentally make a potentially life altering decision. And talk to your legislators about modifying the laws so as to not criminalize ordinary behavior…